Is there any way to solve the heat problem of led line lights

Release date:2018-08-29 Author:华欧小编 Click:

At present, one of the major technical problems of led lighting fixtures is the heat dissipation problem. The poor heat dissipation leads to the led drive power supply and electrolytic capacitors, which have become the short-term development of led lighting fixtures.

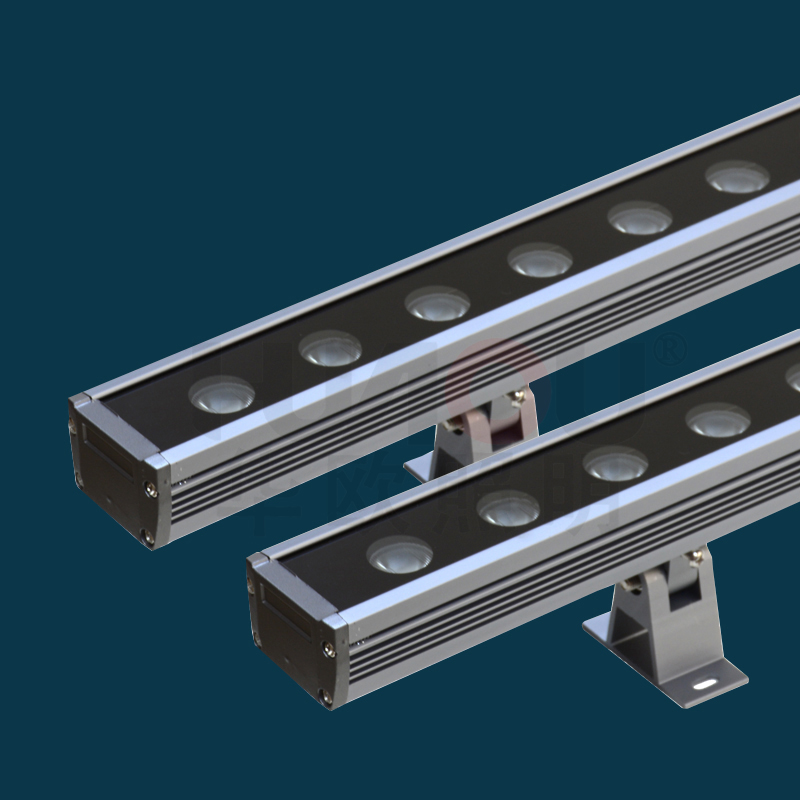

Led line lights rely on simple lines, through the creative design and free segmentation of space, to create a variety of sleek minimalist shape and light and shadow effects, highlighting the ultimate beauty of linear lighting, the future market prospects are considerable. In the past two years, with the popularity of led line lights, more and more lighting manufacturers have participated in it. In recent few large and small exhibitions, the Line Light Pavilion has attracted a lot of attention with its personalization. Due to the influx of a large number of manufacturers, the types of led line lights are also increasing. At present, the lighting industry has a rich line of styles, more than 300 styles, but the structure of these lines is basically similar, the difference is only weight, size and surface technology.

Most LED lighting sources still use low voltage (VF=3.2V), high current (IF=200-700mA) led lamp bead, because the high heat during operation, must use aluminum alloy with high thermal conductivity. There are generally die-cast aluminum radiators, extruded aluminum radiators, and stamped aluminum radiators. The die-cast aluminum radiator is a kind of pressure casting part skill. The liquid zinc-copper-aluminum alloy is poured into the inlet of the die-casting machine, and is die-cast by a die-casting machine to cast a shape heat sink defined by the mold beforehand.

In the LED line lamp, the internal chip is more and more integrated, and a lot of heat is generated during work. The smaller the space, the harder it is. As the junction temperature of the chip increases, the luminous efficiency of the chip also decreases. The higher the junction temperature of the chip, the faster the luminous intensity decreases. The heat of the led chip can not be dissipated, which will accelerate the aging of the chip, which may cause the solder to melt and the chip to fail.

In order to ensure the normal operation of the power type LED, an effective heat dissipation design is required to ensure that the working junction temperature of the LED is within the allowable temperature range. The company has developed the PM260S series of new LED thermal conductive silicone sheets through repeated communication tests with customers. The products have good thermal conductivity, insulation, flexibility and self-adhesiveness. They can be well-applied to the LED chip and the heat-dissipating shell. The gap enables the LED chip to be in full contact with the heat sink member so that heat can be quickly conducted out.

This article URL:http://www.gdhuaou.com/en/news/386.html

Key words:led线条灯,led线条灯品牌,led线条灯厂家

推荐新闻

- Led line light is a 2018-09-10

- Led line lamp manufa 2018-08-29

- What are the charact 2018-09-03

- How to deal with the 2018-08-29

- What are the charact 2018-08-29

- What are the charact 2018-08-29

- What kind of materia 2018-08-29

- How to deal with the 2018-09-13

- Led line lamp brand 2018-08-29

- What are the charact 2018-09-06

Tel:18825002880

Tel:18825002880  Fax:0760-22323720

Fax:0760-22323720  qq:664392963

qq:664392963  Mail:1511832000@qq.com Web:www.gdhuaou.com/en

Mail:1511832000@qq.com Web:www.gdhuaou.com/en Address: No. 19 Cao'an South Road, Dusha Industrial Zone, Cao Erjun, Guzhen Town, Zhongshan City, Guangdong Province

Address: No. 19 Cao'an South Road, Dusha Industrial Zone, Cao Erjun, Guzhen Town, Zhongshan City, Guangdong Province